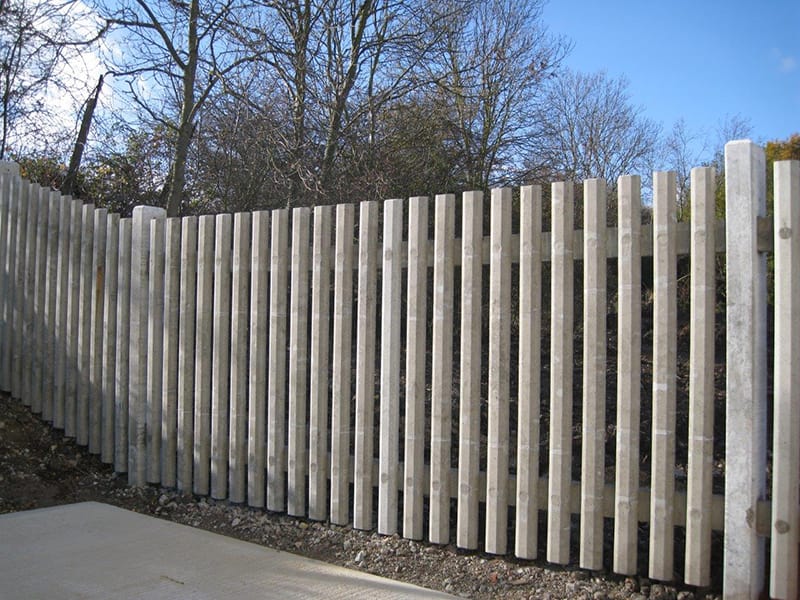

Concrete palisade fencing increases security while also increasing visibility. Concrete palisade fencing is widely regarded as the industry standard, owing to its significant production and construction experience. Since its inception more than two decades ago, has made several changes to the product and manufacturing process. High-frequency vibration and the addition of a light-duty standard (available in a range of different heights) have enhanced overall quality while also broadening the product line offered.

Typical cost is based on materials collected from the factory or installed within a 10-kilometer radius. The cost of transportation and delivery is calculated per kilometer at a reasonable rate. Prices for materials start at

| 1.2m Height | 1.8m Height | 2.4m Height |

| R395 p/m | R520 p/m | R670 p/m |

We’ve been making concrete items, such as concrete palisades and walls, since 1969. Precast walling, concrete palisades for concrete fences, water gulleys, tree rings, basins, window sills, unique poles and panels for house construction, and many other goods are among our offerings. We are the only company that provides a ten-year guarantee on all of our manufactured products.

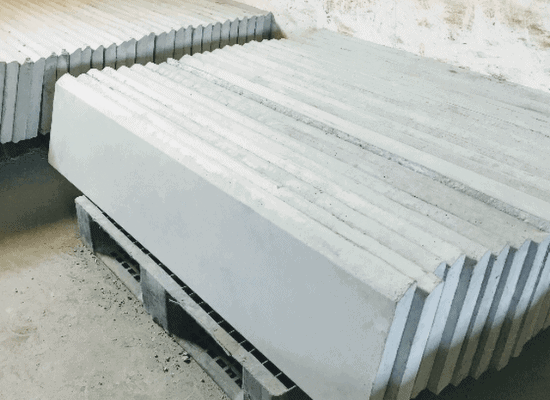

Because they are completely prestressed, our concrete palisades are sturdy and long-lasting. When it comes to strength, pre-stressed is the best. We’re also one of the few companies in the world that make prestressed concrete palisades.

To ensure that our concrete palisades are of the greatest quality, they are put through rigorous stress and pressure testing. Our innovative brackets allow beams to split out in problematic regions, such as clay ground types.

We have been providing the public with the best and highest quality goods on the market for nearly 50 years. The wire strength of our prestressed palisade beams is 1700 MPa.

All of our concrete palisades are tested to a pressure of 40 MPa in order to provide our customers with a trustworthy product that no one else can match.

SECURITY FENCE FOR INDUSTRIAL TYPE PRECAST CONCRETE PALISADE

1.1. IN GENERAL, WORKMANSHIP AND FINISH:

All concrete elements are made of sound concrete that is free of structural flaws. On three sides, all concrete parts have an off-shutter treatment, with a wood floated finish on the fourth. All concrete elements have a minimum cover of 12mm, as per SABS 1372-1983.

1.2. DIMENSION AND SHAPE:

As noted in 2.1, 3.1, and 4.1, all elements must maintain the needed shape and be true to the respective and specified dimensions.

1.3. PERFORMANCE REQUIREMENTS (STRENGTH): All pre-fabricated elements must have a minimum concrete compressive strength of 30 MPa at 28 days, as established by SANS 5836.

1.4. THE CURING PROCESS:

All concrete elements must be treated in accordance with SANS5836 requirements.

1.5. ADDITIONAL STRENGTH:

All steel used for reinforcing in prefabricated elements must be high yield steel with a minimum characteristic strength of 410 MPa and conform to SABS 920 and SABS 920.

SABS 4482 is a standard in the United States.

Rust, loose scale, flux, grease, or oil substances must be removed from all reinforcing steel wires.

2.1. The posts are 3.0m long and slotted to receive the horizontal load-bearing rails, as shown in the picture. The back piece is 140mm wide and tapers to 80mm in the front. The post’s thickness must be 225mm. In a concrete foundation, posts must be spaced at 2.0m intervals. The top of the post is at a 45-degree angle.

2.2. Each post is made up of four high-yield carbon steel bars measuring 4mm by 2900mm in length.

3.1 The pales are 2.4 meters long and include two 10mm holes for 8mm carriage bolts. The pales must have a 75mm thickness. A total of 9 pales are installed per 2-meter segment, spaced at +/- 200mm centers.

3.2. Each pale contains four high-yield carbon steel bars of 4mm x 2350mm in length. The pales are angled at 45 degrees at the top and bottom.

4.1 The rails are 1.98 meters long and have nine x 10mm holes for carriage 8mm bolts. The rails must be 150mm in width and 80mm in depth. The rails are slid into the posts and grouted with a 2 to 1 sand/cement mixture.

4.2. Each rail is made up of four high-yield carbon steel bars measuring 4mm by 1900mm in length.

5.1. Mild steel nuts, bolts, and washers were utilized to erect the fence. At an additional cost, electro galvanised (zinc and chrome) fasteners can be supplied as an option (coastal application).

5.2. All bolt holes are filled with cement mortar, thus no electro galvanized fasteners are required. A 2 to 1 sand/cement mix is used in the grout.

6.1. Each post is set in a 450mm × 450mm concrete foundation hole with a 600mm depth.

6.2. The sizes stated in par. 6.1 are for firm soils; for softer yielding soils, these sizes may need to be increased.

6.3. At 28 days, the foundation must have a minimum pressure of 15 MPa.